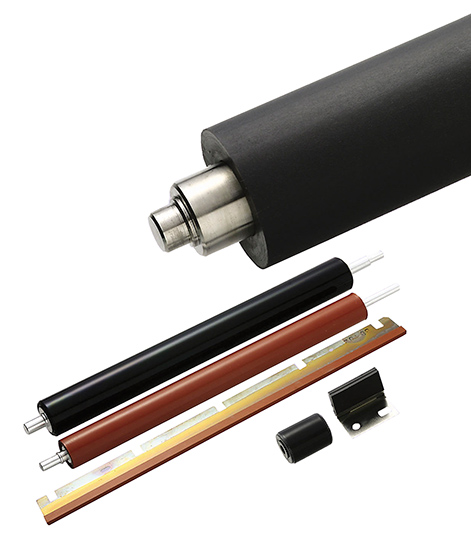

Rolls for Office Machines/Devices

We manufacture mainly rubber rolls used in copier or printer.

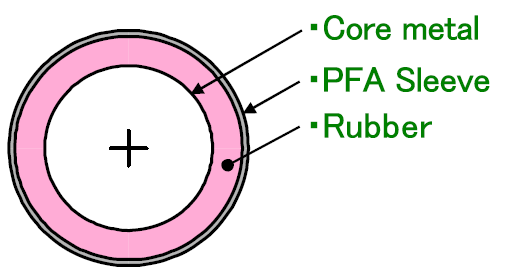

We can provide products that satisfy required characteristics for each application, such as roll covered with rubber on the core metal surface and roll coated with PFA sleeve on the outermost layer.

Please refer to the main rubber characteristics table and request it.

Product Introduction

| Used section | Use | Products | Representative composition |

|---|---|---|---|

| Fixing unit | Fixing roll |

Soft roll |

Surface layer of silicone rubber coated with thin PFA sleeve |

|

Hard roll |

The core coated with thin PFA sleeve |

||

| Pressure roll |

Rubber roll |

Surface layer of core coated with silicone rubber |

|

|

PFA roll |

Surface layer of silicone rubber coated with thin PFA sleeve |

||

|

Sponge roll |

Surface layer of silicone sponge coated with thin PFA sleeve |

||

| Pressure pad |

Silicone pad |

Vulcanization adhesion of silicone rubber to steel plate |

|

| Transport unit | Paper feeding roll |

Paper feeding roll |

Conductive EPDM press fit into core |

|

Paper discharging roll |

Surface layer of silicone sponge coated with thin PFA sleeve |

Feature

- 1. The rollers coated with PFA sleeves

-

By coating surface layer of the silicone rubber with escalope PFA sleeve, it can be used as rolls which excellent in releasability, heat resistance and durability.

Soft fixing roller is superior in a thermal conductivity by using thin and high heat conductivity materials as rubber.

- 2.Backup roller (Auxiliary transfer roller)

- By original rubber combination, a more stable electric property value is provided.

Product shape

| Outside diameter | φ8 or more |

|---|---|

| Total length | A0 size or less |

| Shape | There is regulation by a manufacturing method.(It varies according to rubber thickness.) |

| Rubber thickness | 0.25mm or more |

| PFA sleeves | 30μm or more |

Main characteristics list of rubber

| Types of rubber | Silicone rubber (VMQ) | Ethylene propylene rubber (EPDM) |

Chloroprene rubber (CR) |

|||

|---|---|---|---|---|---|---|

| HTV | LSR | Sponge | ||||

| Primary use |

|

|

|

|

|

|

| Surface layer sleeve coating | ○ | ○ | ○ | ○ | ○ | |

| Hardness | JIS-A | 20~70 | 0~60 | ― | 35~70 | 60, 70 |

| Asker-C | ― | 6~75 | 20~50 | ― | ― | |

| Heat resistance limit temperature | ℃ | 230℃ | 230℃ | 230℃ | 150℃ | 120℃ |

| Heat-resistant safety temperature | ℃ | 180℃ | 180℃ | 180℃ | 120℃ | 100℃ |

| Thermal conductivity | W/m・℃ | 0.2~0.5 | 0.2~1.0 | 0.1~0.2 | ― | ― |

| Compression set | 70℃/22h | ○ | ○ | ○ | ○ | ○ |

| 120℃/22h | ○ | ○ | ○ | △ | × | |

| 180℃/22h | ○ | ○ | △ | × | ― | |

| Volume resistivity | 106Ω・cm or less | ○ | ○ | ○ | ○ | ― |

| 106~1012Ω・cm | ○ | ○ | × | ○ | ― | |

| 1012Ω・cm or more | ○ | ○ | ○ | ○ | ○ | |

- please note that some combinations may be difficult to produce or may not match the values in the table.

In addition to the above rubber materials, if you have demands such as hardness and thermal conductivity, please contact us.